‘Made in China’ is rightly or wrongly a label that for decades has been the butt of cultural jokes carrying connotations of mass produced, poor quality products. For a while it seemed that the rumours were true, at least to the public, with claims of bad quality found to be widely based in fact. We’ve all been forced to rethink who makes our clothes, where they come from and how well they’re made. Luxury powerhouses like Prada, Armani and Mulberry are all investing in retail in Asia, and manufacturing there too. Although no one can claim it’s a fairy tail, China is now home to a number of very high quality and indeed reputable factories that several brands swear by – proving practice really does make perfect. As well as international brands, there are some homegrown talents that are bringing it all in house. We spoke to three young Chinese designers, each of which pride themselves on their exceptional quality and are adamant that ‘Made in China’ will always be best for them.

Dress by Xu Zhi

Angel Chen’s thirst for quality is rooted as much in innovation as it is in creativity. Upon graduating from Central Saint Martins she was named one of i-D Magazine’s top 5 graduates to watch after showing her end of year collection, gaining her work the charming title ‘Chinese Punk’. On her quest for perfection, Angel maintains strong communication with her factory staff to insure the pieces are up to her standard – and, after securing stockists such as Urban Outfitters and Lane Crawford, it’s an investment that seems to be paying off.

Why did you choose to manufacture in China?

As the largest producer of manufactured goods in the world, China is well-known to be a manufacturing powerhouse. Our label benefits from the cheap yet speedy production in China, which is crucial for an independent brand. Although some nearby South-East Asian countries can provide an even lower cost than China nowadays, such as Cambodia, Thailand and Vietnam, China still provides more experience and better quality – at least for now.

How is your relationship with the teams that make your clothes?

We have several factories as our long-time collaborators and we’re really learning from each other as we go. I surprise them with my new and unexpected designs, and they reward me with their patience, understanding and skilful hands.

You continued to be very strict with your quality control – how are you able to maintain this with your factories?

Communication and frequent follow-ups. This is also the reason why I moved my production unit from Shanghai city centre to Suzhou, just next to the plant that makes most of our pieces. Our production team can then follow every single thing from pattern making to mass production and solve the problem immediately with the factory when it appears.

How important is it to your stockists where your pieces are made?

My stockists are more focussed on the design and craftsmanship than the country of origin. It doesn’t matter where the pieces are manufactured, but more whether the quality has reached the stockists’ expectations. They share the same interests as us – that the pieces are made in factories that comply to requirements in areas of safety, local laws and ethical environment. These components are essential to our long-term growth.

What is the attitude in China to ‘Made in China’ products?

I think the answer to this question depends on the product category. But for fashion, many people here are proud that their country’s manufactured goods for luxury brands are selling worldwide.

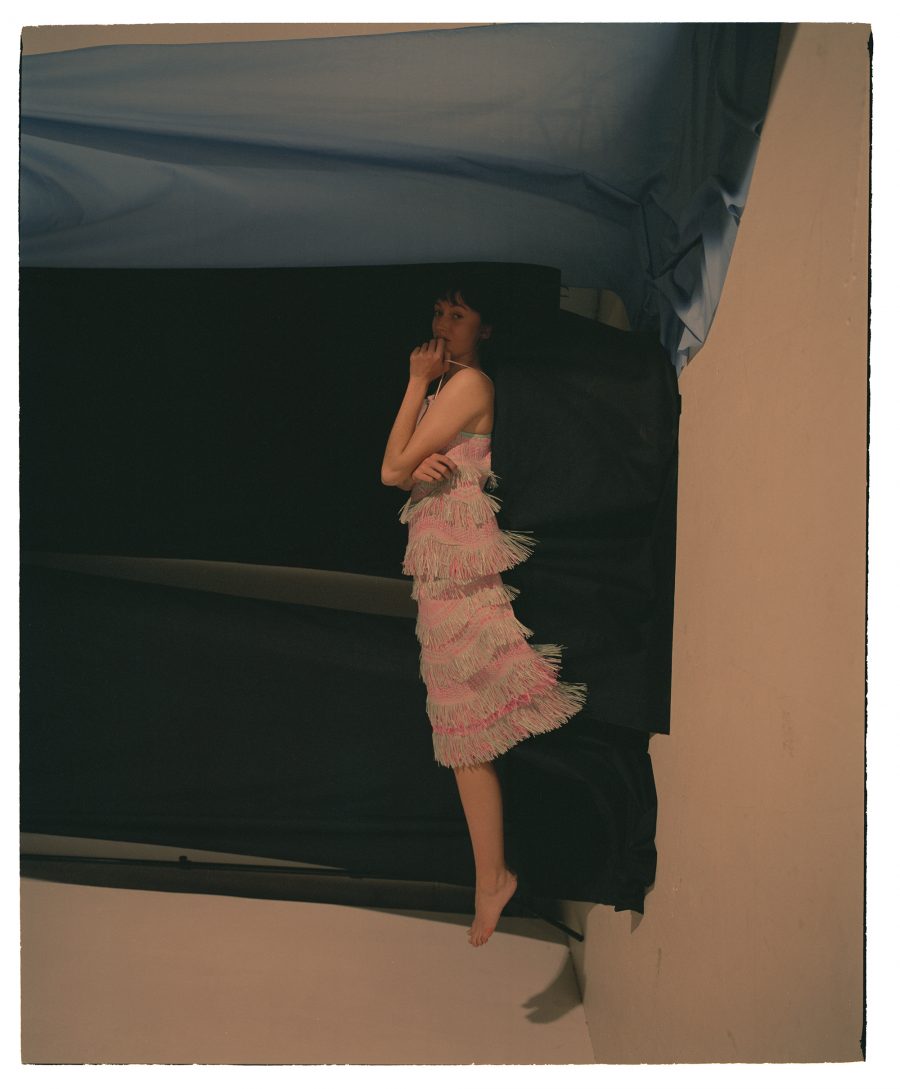

All clothing Angel Chen

With a moderate size piece taking up to a week to complete, the Xu Zhi method of making is not only intricate work, but a huge financial and logistic commitment. With nominations for both the LVMH and Woolmark Prizes under his belt, Xuzhi’s standard of making has become synonymous to the studio. Made up of a combination of hand-braided yarns and complex embroidery, each piece requires an incredible level of skill to execute – a level of skill that has been comfortably found in China.

Were Chinese factories the obvious choice when starting your brand?

Yes. After being the world’s factory for decades, the production system there is very developed and organised. But the landscape of manufacturing is changing as people see the need to develop unique relationships with creative young businesses.

You have a very specific making technique – was it difficult find a factory capable of the quality you wanted to achieve?

We started to work with a small factory which used to produce wedding dresses – so we didn’t really need to explain about quality. They made a really great transition with us going into ready to wear production with so much hand work.

Has the process influenced how you think about your collections when designing?

Yes definitely, in a positive way. It really gives you perspective of how things are done in the system, it can be done nicely but still cost effectively. They are always seeking more efficient methods.

Have you encountered any negativity regarding your collections’ ‘Made in China’ origins?

Not really, and to be honest if it weren’t for ‘Made in China’, this intricate technique that we are using wouldn’t be commercially possible for our brand.

How do you see the future of luxury manufacturing evolving over the next decade?

There will be more and more factories like mine that allow a lot of hand-craft work to be possible at a more accessible price point as the demand for “ affordable luxury” grows. But there will be also more people seeking true Haute Couture as uniqueness become more and more difficult to own due to the digital revolution and globalisation.

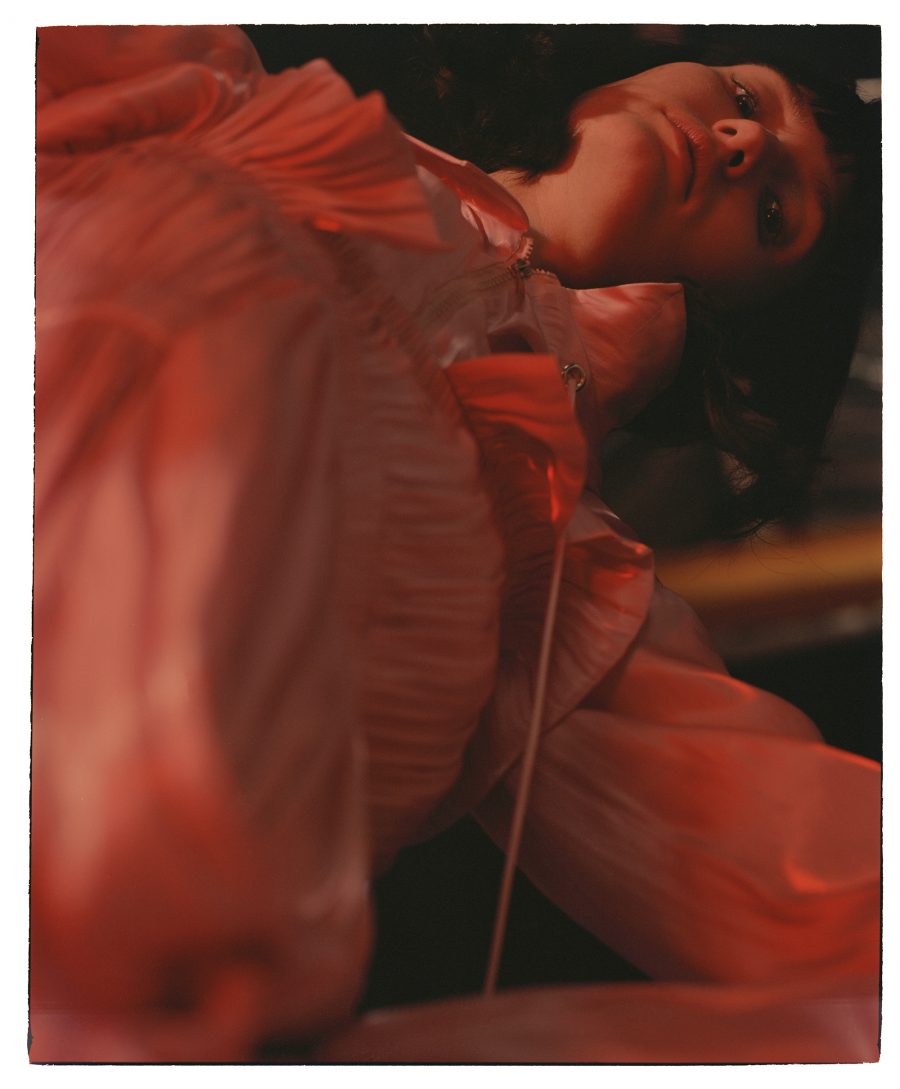

All Clothes Xu Zhi

Born in Canada, Steven Tai went on to study at Central Saint Martins in London where he honed his now signature ‘awkward-chic’ aesthetic. It was this along with his innovative use of textiles that has since won him an array of accolades including the Chloe award, Vogue Italia’s ‘Vogue Talents’ exhibition feature and the ANDAM award. In regards to quality however, Tai can’t find anywhere better than home…quite literally – with his family running a prestigious factory in China where his collections are now made.

Your family have their own factory in China – did it already specialise in high-end production before you began using it?

They actually produced technical sportswear garments for cycling competitions. So when we started making ready-to-wear, a completely different set of skills were required and all the seamstresses had to change their method of sewing.

How has working with your family business influenced your collections?

It is an incredible blessing to work with my family. For example, we didn’t have to worry about production minimums at the start of the business. Which allowed us to display and sell garments that were more image driven rather than commercially focused. It also allowed us to make quick changes to adapt to the market without too many complications. It also allows us to develop each collection rapidly so we can fine-tune each piece until we are completely satisfied with the results. Lastly, and most importantly, I get to communicate with my mother everyday and that is the best part of it all.

How easy has it been to keep a consistent level of quality throughout your collections?

Even though it is a family business, it is still tricky to ensure the quality of each collection as we adapt and improve our finishings season after season. Luckily, we can stay in the factory and teach the team the new finishings every time. More importantly, there is efficient communication and trust between us, making the entire process a lot easier.

Have you sensed a change in attitudes towards Chinese manufacturing, particularly of high-end items, in recent years?

Yes definitely. Previously, Chinese manufacturing focused on low-cost, high-volume products as a way to generate profit. However, as more and more young designers become established in China, manufacturers are opening their doors to these designers and are finally seeing that a higher price point with a lower minimum can be a profitable structure too.

Would you ever produce anywhere other than China?

I have looked at other countries. I think it is heavily dependent on where we sell to and where it is delivered from, which will influence the duty significantly. But as the answers above show, the benefits really have supported us and will continue to do so. Therefore it is difficult to imagine us moving our entire production elsewhere.